HDPE in its pellet form is normally used directly for manufacturing goods, such as bottles, carrier bags, pipes and many others, but before we get to buy these revolutionary creations, the pellets must first undergo the necessary manufacturing processes.

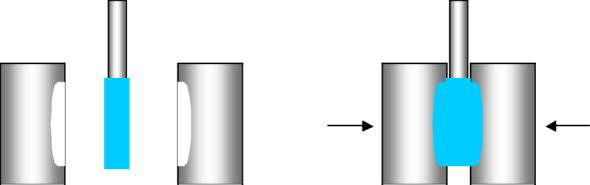

First up is the blow moulding process. This method is the standard method for producing shapes such as bottles or any containers with significant rounding at the edges that are characteristic of the blow moulding procedure. They begin by melting down the HDPE pellets and extruding the now molten pellets through a die to form a hollow tube. The tube (also called a parison) is then enclosed by the mould and air is blown into the tube to expand the material into the mould’s shape (figure 4-1). In the process the finished bottle, container or part is cooled, solidifying the HDPE in its new shape. (Charloma Inc., n.d.)

Figure 4-1 (UNSW Sydney, n.d.)

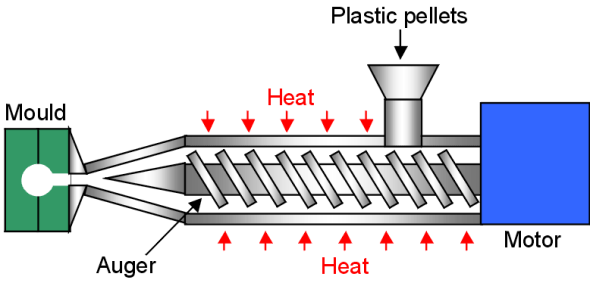

Next, we have the injection moulding process. Injection moulding is the most precise way that HDPE and many other plastics can be produced. This method is usually used for the making of precise parts that require relatively fine tolerances. Examples include but are not limited to: airtight lids for containers, minute pipe fittings for home aquariums and propellers for hobbyist drones. The machinery consists mainly of a feed hopper, where HDPE pellets are added into the machine, a screw mechanism (sometimes called an auger) and the final mould. After being added to the hopper, the pellets enter a cylinder with the large threaded screw inside, where the pellets are melted down and forced into the mould by rotating the screw. The screw has large separations between the teeth of the thread, allowing enough material to enter the mould. As the melted pellets pass out of the screw mechanism, they encounter a short nozzle that increases the pressure in the exiting mixture to form the required part to great detail. Upon “injection” the new part is rapidly cooled and the mould opened for a worker or other mechanism to remove the newly made part. The moulds used in these machines vary in accuracy and lifetime, both of which make the moulds extremely expensive, therefore it is wise to only use this method of manufacturing when a sufficient number of units are to be produced for the cost of the mould to be justified. This is similar to the extrusion process, which essentially uses the same type of apparatus, but instead of the plastic entering a

mould it is merely extruded. (Charloma Inc., n.d.)

Figure 4-2 (UNSW Sydney, n.d.)

Last but certainly not least we have rotational moulding or roto moulding as it is commonly known. Roto Moulding is used for making robust, hollow products that do not require a great deal of precision throughout the design. Common products that are made by rotational moulding include: kayaks, air ducts, chute tubes and hydraulic tanks. The process starts with HDPE powder in a closed mould, that is attached to a mechanical arm. The powder filled mould then enters an oven for a predetermined amount of time, while it is rotated biaxially by the mechanical arm, allowing the powder to melt and coat the inside of the mould. After the required time in the oven, the mould is cooled until the part can safely be removed from the mould. Any minor tooling necessary is done and then the product is complete. (Charloma Inc., n.d.)